Free Trade Agreements (FTAs) present stellar opportunities for companies to drive substantial cost savings, gain competitive advantage and optimize their supply chains.

The recently signed Regional Comprehensive Economic Partnership (RCEP) and the EU-Vietnam Free Trade Agreement (EVFTA), that came into effect in August this year, could significantly benefit businesses in APAC. Hot on their trail is the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP), making these FTAs ripe for CFOs’ picking.

COVID-19, US-China trade tensions, and geopolitical shifts have pulled the cozy rug from under traditional supply chains and trade routes, changing them forever. Through proactive business partnering, leadership and decisive action, CFOs can convert this crisis into a golden opportunity to revolutionize their supply chain strategy, accelerate business growth and boost profitability.

Mining the financial benefits of the new FTAs is central to this strategy.

Why the FTA-led approach?

The ongoing crisis has forced companies to transform their supply chain. But very few have capitalized on this opportunity to reap cost benefits and gain a competitive advantage from FTAs.

If used to their fullest, FTAs offer game-changing savings for businesses. RCEP will eliminate a range of tariffs within what is now the world’s largest trading bloc covering about 30% of the world GDP and population across China, Japan, South Korea, Australia, New Zealand and ASEAN. The EVFTA has scrapped duties on 99% of all goods traded between both sides, while the CPTPP, once fully ratified, will eliminate more than 98% of tariffs among eleven signatories, including Japan, Australia, New Zealand, Singapore, Vietnam, Mexico and Canada.

CFOs need to analyze not only if their company is utilizing FTAs, but also how to drive maximum cost savings.

How much are you saving using FTAs?

These are the questions that will drive up your profitability. Let’s address them.

How are you utilizing FTAs? If your documentation is being prepared manually, the risk of errors is compounded and may lead to penalties at multiple stages of your supply chain – from compliance breaches to penalties from buyers if the error leads to customs or shipping delays. Manual reporting can be fraught with errors and take several FTE hours or even days to complete, whereas a digitized platform can help you achieve the same task with zero errors in a matter of minutes.

Automated use of FTAs can also help uncover new opportunities for tariff reductions for your business, without having to trawl information from a range of Excel files, systems and websites.

While in theory, FTAs offer valuable savings, it is critical for CFOs to get full visibility into the actual savings and efficiency gains to measure ROI. Accessing data at your fingertips to be able to track the savings is an invaluable tool in optimizing the strategic management of your supply chains.

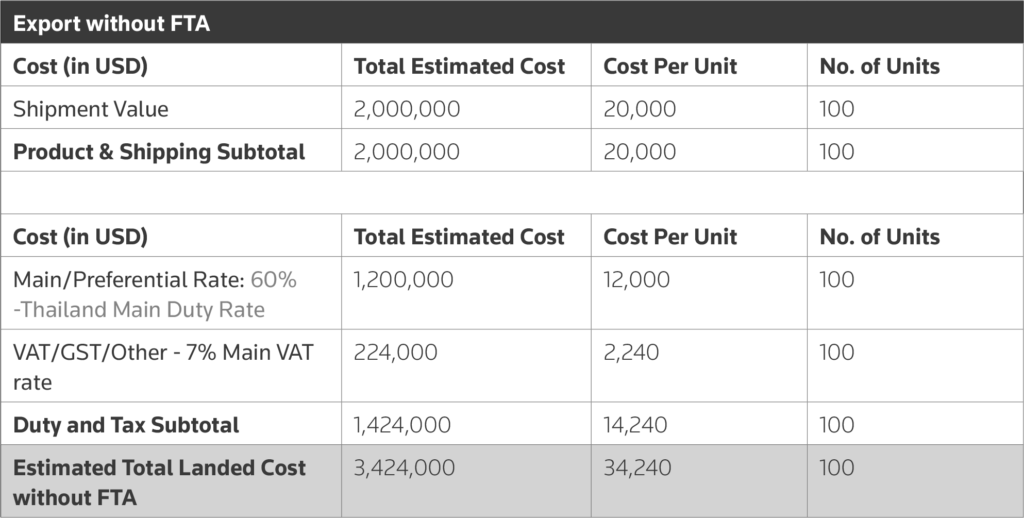

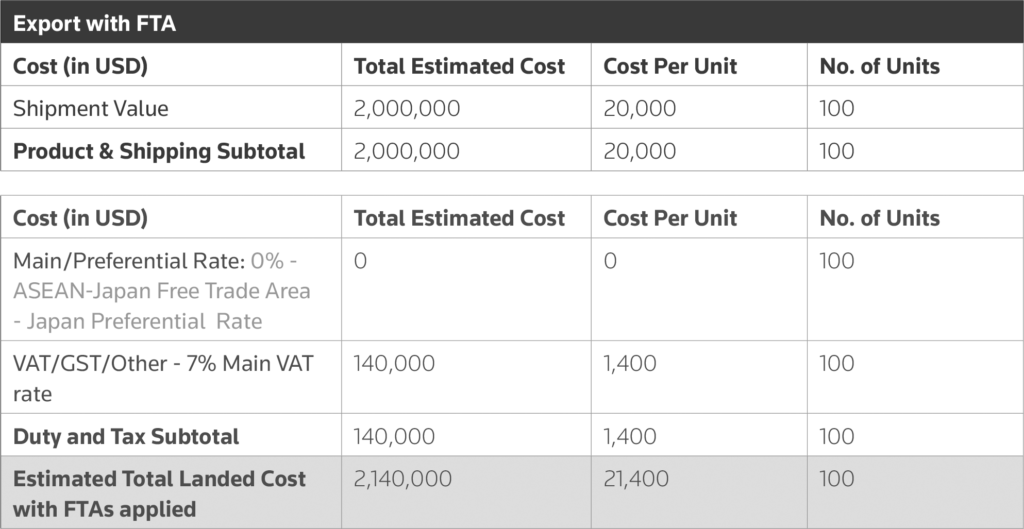

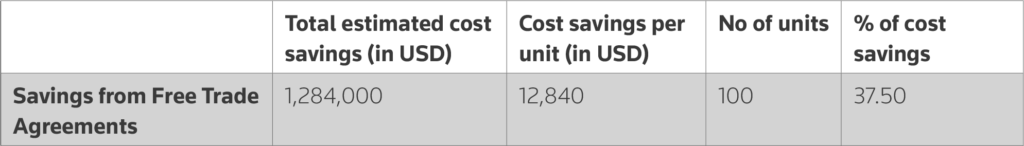

Below is an example of how FTA adoption helps slash customs duties and reduce landed cost.

Impact of FTAs on your total landed cost. Bringing 37.5% savings in your inventory expenses.

Landed cost is a critical factor affecting a company’s pricing and profitability, but accurately calculating it can be very complex and challenging. If one of its many components has not been tracked or optimised correctly, there is the potential for a massive hike in costs.

The table above shows that when the duty and tax benefits of this FTA were applied in this example of 100 units, landed cost was reduced by a whopping 37.5% from USD 3.42 M to 2.14 M bringing down the cost per unit from USD 34,200 to USD 21,400.

Reducing landed cost can have a substantial impact on your P&L and price competitiveness. By passing on some of this cost-benefit to consumers, companies could drive up demand, grow their revenue and market share.

Supply chain agility

More broadly, it’s crucial to have an agile supply chain strategy that allows you to look at a range of scenarios. When supply chains, markets and regulations are changing daily, being able to consider multiple import/export options and compare the impact of changing factors on the movement of goods is paramount.

Automated analysis of global trade processes can consider factors such as sanctions, risks, projected payment of duties and taxes, ease of doing business in a country and, of course, regulatory changes.

Data analytics allow you to work out in advance, precisely how a supply chain will function and plan different scenarios, should risks arise. You can pinpoint incorrect product classifications, and where duties are being overpaid, which is vital information to share with your team.

Digitization: cost reduction from data consolidation

Digitization can ensure all relevant compliance obligations are met but, most importantly, it can deliver the options that offer the most significant savings for your company.

By consolidating data, through integration with the ERP or supply chain partners, into one platform, you can have clear visibility to determine how much you are spending on customs duties by geography, business unit, product and supplier.

With this insight, you can identify new ways to reduce cost, such as adjusting your sourcing strategy.

When one MNC replaced their decentralized processes and manual calculations with a central digitized platform, they enjoyed savings of more than US$1 million annually. In another case, an MNC’s savings on trans-border duties and taxes after digitization amounted to US$100 million.

The more things change, the more opportunities you have to build a supply chain strategy that can make a world of difference to your bottom line and your business. Are you ready to revolutionize your supply chain to drive growth?

Technology and content to enable you today and tomorrow

Our goal is to empower CFOs with mission-critical content and technology so they can get the best out of their supply chains and global trade. Learn more.