Free Trade Agreements (FTAs) can provide value at many steps of a supply chain strategy. All trade agreements provide benefits or preferences to member firms that non-member companies do not receive.

While not every market in Asia is connected together via FTAs, with more than 300 active agreements in the region, it is highly likely that an FTA will match trade flows. In many markets, firms may have options with more than one agreement covering the same pair of countries. As an example, Singapore and New Zealand currently have four different agreements in place between them with slightly different benefits available to firms from each deal.

Companies can leverage benefits from FTAs in many ways: by choosing the best FTA to import or export to a market, or by expanding or building the supply chain based on the best location for production and sourcing of inputs.

Firms that understand how to harness trade deals should consider their sourcing and production decisions and adjust compliance actions to ensure continued access to global markets, save costs, reduce uncertainty, and raise efficiency to gain a competitive advantage in an uncertain world.

There are four key factors in the development of an FTA optimization strategy:

- Sourcing Location

- Manufacturing Location

- Distribution Set-Up

- Priority End Markets

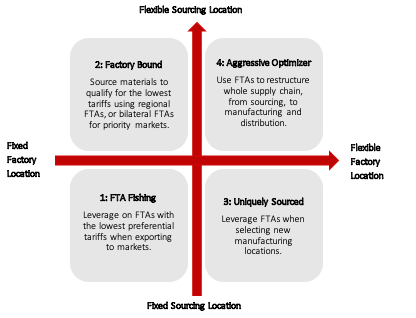

Based on the flexibility of their factory location and the sources of their raw materials and production inputs, companies can adopt four different types of FTA optimization strategies shown in the figure below.

Figure 1: Scenarios for FTA Optimization

Scenario 1: FTA Fishing. In FTA Fishing, companies have limited flexibility in both the location of their factory and the location of origin of the raw materials, parts or components that are inputs to their products. This may be due to existing sunk costs in a capital-intensive factory location or limited alternatives in the location of their input sources. Often, smaller firms face large constraints in relocating production and sourcing decisions.

Despite an inability to move locations, firms in FTA Fishing can still utilize FTAs, by searching for agreements that provide the biggest benefits, such as lower tariff rates or even duty-free treatment, reductions in compliance costs, or improved services and investment coverage and protection building on their existing supply chain footprint.

FTAs are not automatically applied. Only firms that ask for preferential treatment and meet the rules of the agreement are eligible for benefits like lower tariff rates.

The headquarters location of a firm is less relevant to FTAs than the location of production processes and end market. Even foreign-registered firms may be able to use FTAs as long as they follow the provisions of the agreement.

Scenario 2: Factory Bound. In the Factory Bound scenario, companies have greater flexibility when it comes to sourcing for raw materials and inputs from alternative countries, but remain limited in their ability to relocate the production process. This may be due to existing sunk costs, or substantial cost savings associated with a given production location.

Factory Bound companies can use FTAs to source inputs like parts, components and raw materials to their production processes at lower costs including potential duty-free treatment for inbound materials and with greater certainty. Such firms can adjust their sourcing decisions to fulfil the rules of origin requirements across FTAs from their existing production location.

Scenario 3: Uniquely Sourced. In the Uniquely Sourced scenario, companies have flexibility in locating the main production site for the factory. However, choices for the originating location of key raw materials remain fixed. This may be due to the uniqueness or exclusivity of the raw material, such as luxury items or agricultural products that can only be produced in a single region.

In this case, Uniquely Sourced companies can still take account of the cost savings that FTAs provide in selecting the best locations for their production to export and to expand into new key markets.

Scenario 4: Aggressive Optimizer. In the Aggressive Optimizer scenario, the company has greater flexibility in locating both the production and sourcing of products, for example, when deciding on the location of a new production plant in a region with wide availability of inputs.

Aggressive Optimizers can therefore conduct a full network analysis of the FTAs in the region to optimize both location and sourcing decisions when constructing supply chains, and include tariff duties and trade compliance costs in its overall cost estimates.

Subsequent Unlocking the Chain pieces will unpack these four scenarios and give examples of each approach.